Food & Beverage Cleaning Services: From Audits to 24/7 Washdowns

Summary

- Sector-Specific Mastery: Unlike generalist providers, our bespoke protocols for bakeries, breweries, and pharmaceutical plants address unique challenges—from dismantling complex mixers for allergen removal to managing overnight CIP validations.

- Advanced Risk Mitigation: Utilising cutting-edge technologies such as Cryogenic Cleaning for carbonised deposits and FaST foam scrubbing for slip reduction, we deliver superior results that protect both your workforce and your brand reputation.

- Audit-Ready Assurance: With a robust framework of accreditations (ISO 9001, 14001, SafeContractor) and a "Systematic" documentation matrix, we ensure you are always prepared for BRCGS, retailer, and regulatory audits.

The Specialist Partner: Why Regulated Industries Demand More Than "Clean"

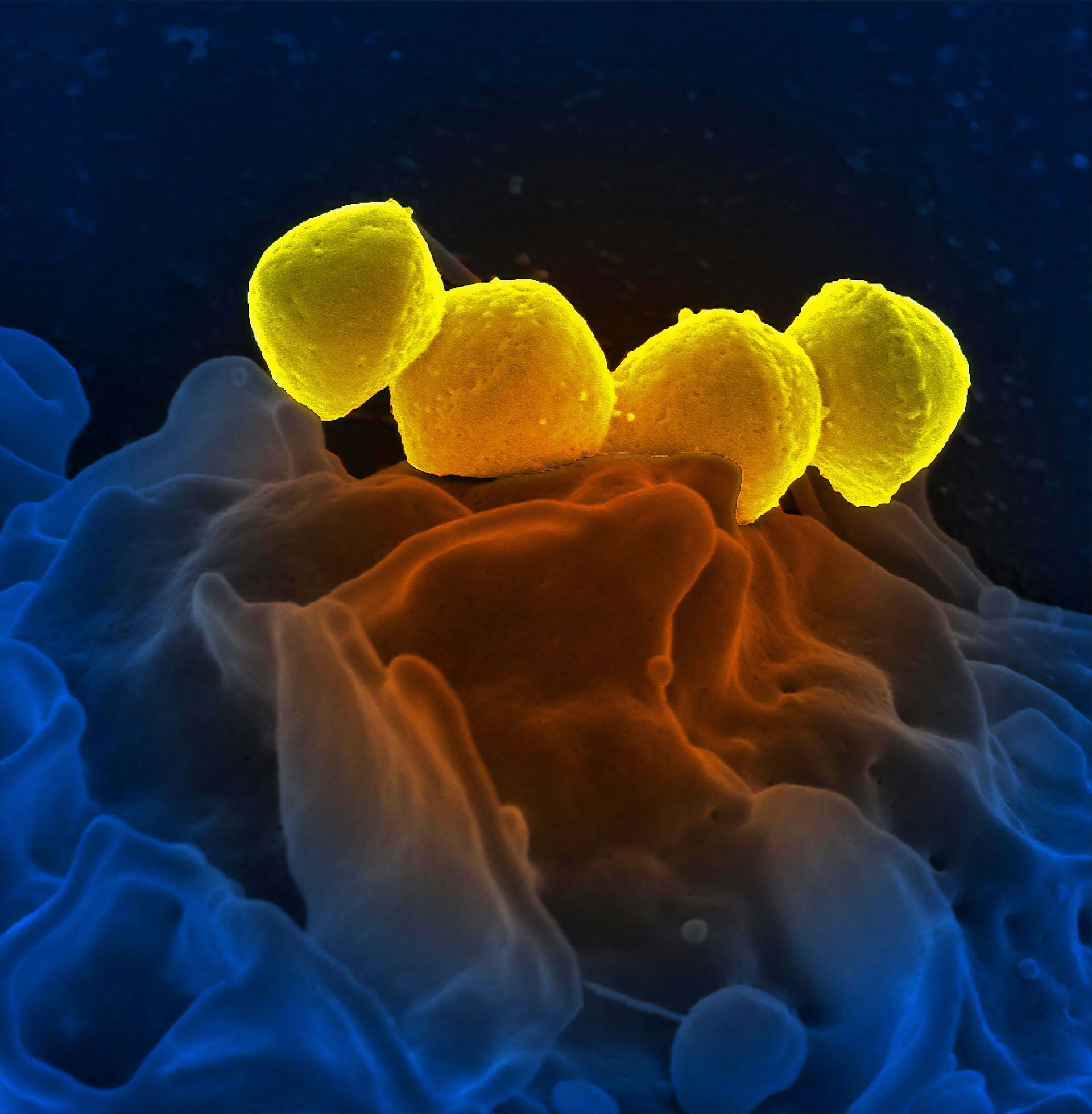

In the high-stakes world of food and pharmaceutical production, "clean" is a relative term. To a general facilities management provider, a clean floor is one that looks presentable. To a Technical Manager preparing for an unannounced retailer audit, a clean floor is one that has been sanitised using validated chemical concentrations, with ATP swab results documented to prove the absence of microbial harbourage points.

At Hygiene Group, we understand this distinction implicitly. For over 35 years, we have operated not merely as cleaners, but as strategic partners to the UK’s most demanding industries. Our ethos is built on deep specialisation; we do not dilute our focus with non-critical sectors. Instead, we dedicate our resources solely to the food, beverage, and pharmaceutical industries, where hygiene is a critical component of compliance, safety, and brand protection.

The difference between a pass and a fail in an audit often lies in the details—the biofilm in a hard-to-reach seal, the allergen residue in a mixer, or the documentation gap in a cleaning schedule. Our article explores how a specialist approach to food & beverage cleaning services protects your licence to operate and drives operational excellence.

Engineering Hygiene: A Technical Approach to Food Manufacturing

The challenges facing a modern food processing plant are multifaceted. Production speeds are increasing, changeover times are shrinking, and the regulatory burden regarding allergens and pathogens is heavier than ever. A "mop and bucket" approach is obsolete. We employ a systematic, engineering-led methodology that integrates seamlessly with your production schedule.

The Bakery Sector: Managing Particulates and Machinery

Bakeries present a unique set of hygiene challenges, primarily driven by flour dust—a significant explosion hazard and respiratory risk—and by the complexity of dough-handling equipment.

- Complex Machinery Disassembly: Our teams are trained to carefully dismantle and clean intricate equipment such as high-speed slicers, wrapping machinery, provers, and industrial mixers. We understand that a superficial wipe-down is insufficient for allergen control.

- Changeover Protocols: We provide rapid, validated product changeover cleans that allow you to switch from allergen-containing to non-allergen runs with confidence.

- High-Level Flour Removal: Utilising explosion-proof vacuums and, where necessary, rope access teams, we eliminate dust accumulation on overhead structures, mitigating fire risks and preventing product contamination from falling debris.

Breweries: Combatting Biofilm and Yeast Residue

In the brewing sector, the enemy is often invisible. Wild yeasts and bacteria can ruin entire batches if fermentation vessels and filling lines are not sterilised to an exacting standard. Developing and delivering the complex cleaning solutions that breweries require is second nature to our teams. We ensure that your distinct flavour profiles are preserved by eliminating cross-contamination risks through rigorous chemical dosing and dwell-time management.

The Allergen Challenge: Validation and Verification

With the prevalence of life-threatening food allergies rising, the margin for error in food processing plant cleaning is zero. In facilities where an allergen is present in some products but not others, the manufacturer must ensure process lines are sterile between runs.

- Detailed Dismantling: Equipment that is hard to clean in situ is dismantled.

- ATP Validation: We utilise Adenosine Triphosphate (ATP) and rapid test kits to validate the cleaning process immediately, providing data-backed assurance before production restarts.

Beyond Standard Methods: Advanced Cleaning Technologies

To deliver the "unrivalled" level of expertise our clients expect, we continuously invest in advanced technologies that solve specific operational headaches. These innovations not only improve hygiene standards but also enhance safety and efficiency.

Cryogenic Cleaning (Dry Ice Blasting)

For stubborn, baked-on residues—common in baking and frying operations—traditional water-based methods often fail or require excessive downtime for drying.

- The Process: Solid pellets of carbon dioxide are accelerated by an air jet onto the surface. Upon impact, they freeze the residue (thermal shock) and sublime (turn to gas), expanding to blast the debris away.

- The Benefit: This leaves a 100% dry, clean surface with no secondary waste stream. It is particularly effective on carbonised or crystallised deposits that would normally require harsh caustic gels, thus eliminating chemical risks to your staff and equipment.

FaST Floor Scrubbing Technology

Slips and falls are a major safety concern in wet production environments. We utilise FaST floor scrubbing technology, a technique adapted from the meat industry.

- The Mechanism: The system deposits a fast-collapsing foam onto the floor. This foam penetrates uneven surfaces more effectively than liquid water.

- The Outcome: The vacuum recovery system leaves the floor significantly drier than conventional methods, reducing slip hazards immediately. Furthermore, it uses less water and chemicals, supporting your environmental sustainability goals.

Pharmaceutical Hygiene: Meeting GMP Standards

While our heritage is strong in food, our rigour makes us the ideal partner for the pharmaceutical sector. Cleaning for the food and pharma sectors requires a higher level of discipline, adhering strictly to Good Manufacturing Practice (GMP).

Confined Space and Silo Cleaning

Many pharmaceutical and food ingredients are stored in bulk silos that pose deadly risks due to breathable atmospheres and engulfment.

- Specialist Safety Teams: Our silo and tank cleaning teams are fully trained in confined space entry, search and rescue, and the use of self-contained breathing apparatus.

- Risk Assessment: Every entry is governed by a comprehensive risk assessment covering entry, exit, product hazards, and emergency procedures. We do not cut corners on safety.

CIP Optimisation and Support

We offer more than just manual cleaning. We can deploy trained staff to operate Cleaning-in-Place (CIP) systems for batch production or post-campaign cleans. Uniquely, our staff can work overnight, releasing your production staff to focus on manufacturing, while we deliver a fully validated clean to GMP standards.

The Commercial Interface: Where Production Meets Administration

While the production floor is the heart of your operation, the surrounding environment—offices, canteens, and washrooms—plays a vital role in staff morale and visitor impression. We offer commercial cleaning services that maintain the same high standards as our industrial work.

- Laboratory Cleaning: We extend our GMP knowledge to QC laboratories, ensuring testing environments remain contaminant-free.

- Staff Welfare Facilities: High-traffic areas like canteens and locker rooms are potential vectors for pathogen spread (e.g., Norovirus). We implement hospital-grade disinfection protocols for touchpoints to protect your workforce's health and reduce absenteeism.

- Technical Advice: We don't just clean; we advise. If your kitchen extraction system poses a fire risk due to grease buildup, we provide a comprehensive extraction cleaning programme to maintain efficiency and insurance compliance.

Systematic Reliability: The Audit Defence Framework

The primary motivation for many of our clients is the looming pressure of third-party audits. Whether it is BRCGS, ISO 22000, or a retailer’s specific code of practice, hygiene services for food factories must produce evidence as well as cleanliness.

Our service is built on a "Systematic" pillar. We don't just say we cleaned it; we prove it.

- Bespoke Cleaning Manuals: Every site has a tailored manual detailing the scope of works, chemicals used (with COSHH data), and method statements.

- The Matrix System: Schedules of work are documented using a matrix chart. This visual tool allows for forward planning, ensuring that periodic deep cleans (e.g., evaporators, high-level pipework) are scheduled during planned downtime rather than missed.

- Real-Time Verification: Our supervisors conduct post-clean inspections with your technical team, signing off on areas only when they meet the agreed standard. This collaborative sign-off process is why client testimonials confirm our work leads to "very positive comments from the external auditor".

Investors in People: The Value of a Stable Workforce

In an industry plagued by high staff turnover, Hygiene Group stands apart. We hold a silver-level accreditation with Investors in People, a relationship spanning over 20 years.

Why does this matter to a Plant Manager?

- Consistency: You see the same faces. Our operatives know your site, your safety rules, and your specific machinery quirks.

- Competence: A stable workforce allows for deep training. Our staff are not transient agency workers; they are skilled professionals trained in chemical safety, machinery isolation, and microbiology awareness.

- Security: High retention means fewer security risks and less time spent inducting new starters.

A Strategic Partnership for Operational Excellence

In the regulated sectors of food and pharma, a generalist cleaning provider is a risk. A specialist partner is an asset.

Hygiene Group offers more than labour and chemicals. We offer peace of mind. We provide the expertise to navigate complex audits, the technology to solve stubborn hygiene problems, and the reliability of a workforce that cares as much about your product safety as you do.

If you are looking for a food & beverage cleaning services partner who speaks your language and delivers measurable results, let’s discuss your site’s specific requirements.

Contact Our Technical Team

Ready to upgrade your hygiene strategy? Contact us today to arrange a site survey or discuss your specific audit challenges.

- Phone: 0121 451 3211

- Email: enquiries@hygiene.co.uk