Cleaning Services by Sector: How to Build an Industry-Specific Hygiene Plan

A generic cleaning rota is insufficient and, in high-stakes industries, dangerous. A robust hygiene strategy must be built on a deep understanding of sector-specific risks, processes, and compliance mandates. Our guide provides a systematic framework for Technical and Quality Managers to develop a bespoke, audit-ready hygiene plan. We will analyse the distinct requirements for the food and beverage, pharmaceutical, and other specialist manufacturing sectors, focusing on a results-oriented approach that mitigates risk and ensures compliance.

Why a One-Size-Fits-All Approach to Industrial Hygiene Fails

For a Technical Manager, Quality Manager, or Plant Manager in a regulated industry, hygiene is not a superficial matter of appearance. It is a critical control point, a core component of your operational integrity, and fundamental to brand protection.

The reality is that the hygiene standards, risks, and audit requirements of a BRCGS-accredited food processor are fundamentally different from those of a GMP-compliant pharmaceutical plant. Both are worlds away from the needs of a high-tech data centre or an automotive manufacturer.

Yet, many businesses are still serviced by generalist facilities management (FM) providers who apply a one-size-fits-all model to specialist environments. This approach inherently fails to manage sector-specific risks, leaving your operation exposed to potential contamination, product recalls, and critical audit failures.

Building a successful hygiene plan is not about simply "cleaning." It involves implementing a systematic and verifiable process tailored to your specific industry. This article explores the core principles of cleaning services by sector and outlines how to develop a plan that yields tangible, auditable results.

The Foundation: A Systematic Approach to All Sector-Specific Hygiene Services

Before differentiating between industries, we must establish the non-negotiable foundation: a methodical and process-driven approach. Any specialist partner must be able to demonstrate a systematic process for developing, implementing, and verifying their sector specific hygiene services.

At Hygiene Group, our 35 years of experience have shown that a successful partnership is always built on this four-step methodology:

- Specialist Site Survey and Risk Assessment: The plan must begin with a deep, technical survey conducted by experts who understand your industry. This involves identifying your specific contamination risks, analysing process flows, and, most importantly, understanding the precise standards of your third-party auditors (e.g., BRCGS, retailer-specific, MHRA).

- Bespoke Plan Development: Based on the assessment, a detailed, bespoke specification is created. This document, including Risk Assessments and Method Statements (RAMS), outlines the exact methodologies, frequencies, equipment, and chemical protocols required for the project. This is a technical document, not a generic cleaning rota.

- Accredited, Specialist Execution: The plan is executed by a stable, highly-trained, and properly equipped team. This is where our 20-year silver-level Investors in People accreditation becomes a direct client benefit. You are serviced by dedicated specialists, not a revolving door of generalist contractors, ensuring reliability and consistently high standards.

- Verification, Reporting, and Auditable Records: The process concludes with robust verification and the provision of all necessary documentation. This creates a clear, auditable trail that demonstrates your compliance, providing peace of mind and positive feedback when your external auditors arrive on site.

The High-Stakes Sector: Food & Beverage Cleaning Solutions

For the food and beverage industry, hygiene is the principal line of defence against microbial risk, allergen cross-contamination, and pest harbourage. An audit failure here does not just mean non-conformance; it can also result in delisting by a major retailer.

A plan for food & beverage cleaning solutions must therefore be results-oriented, focusing on mitigating these specific risks.

Key Focus Areas for Food & Beverage:

- Audit Readiness (BRCGS & Retailer): The entire plan must be reverse-engineered from the standards set by the BRCGS Global Standard for Food Safety and the specific addenda of major retailers. The goal is to ensure that every clean provides "very positive comments from the external auditor."

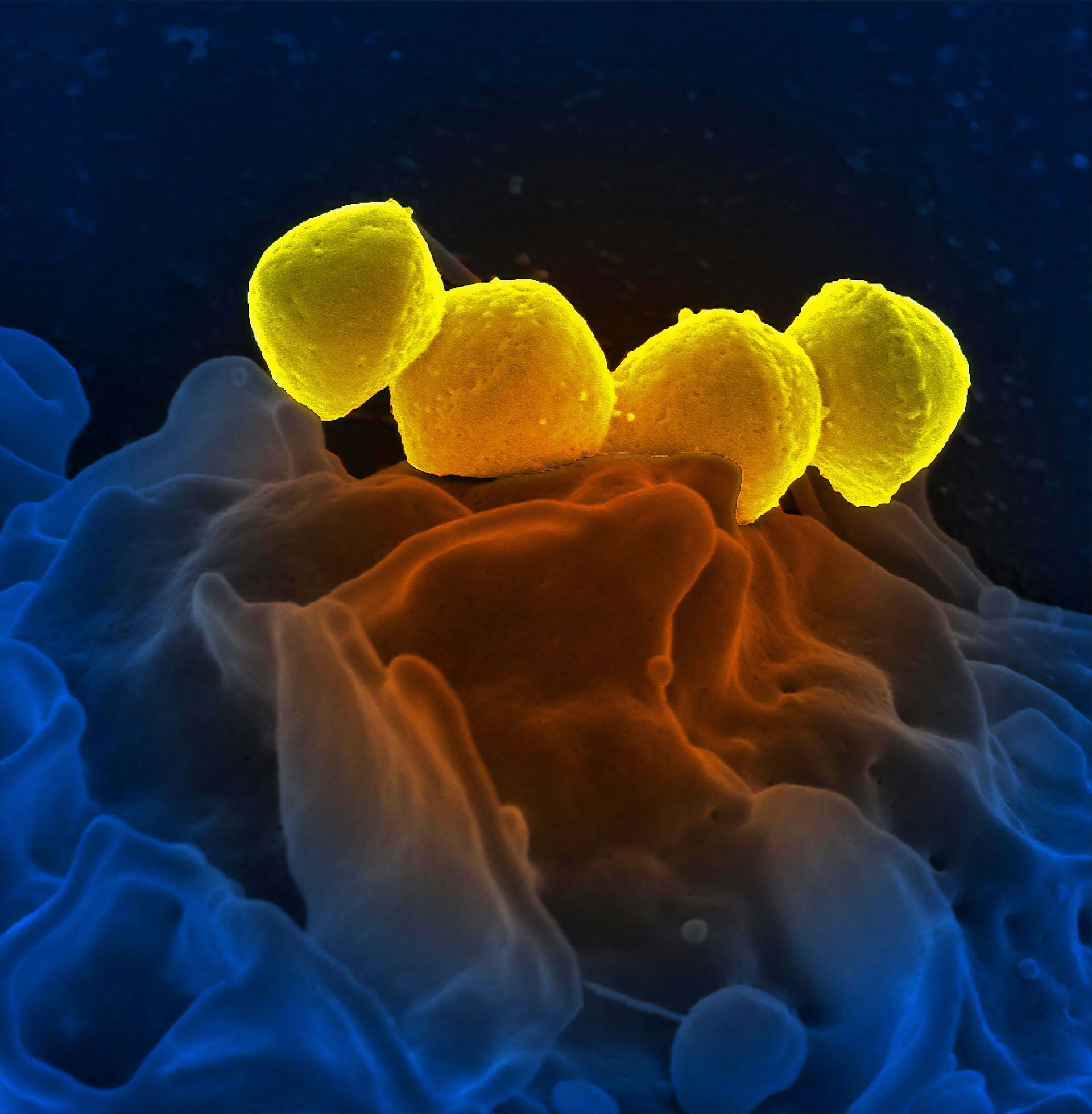

- Microbial & Pathogen Control: The primary objective is the demonstrable control of pathogens like Listeria, Salmonella, and E. coli. This requires specialist knowledge of cleaning at a microbial level, including the correct application of foam cleaning, sanitation protocols, and, where necessary, periodic swabbing and validation.

- Allergen Cross-Contamination Management: With allergens as a leading cause of product recalls, the hygiene plan must include a robust, verifiable process for "allergen cleans." This involves deep, methodical cleaning of processing lines between production runs to ensure all allergenic protein residues are removed.

- Specialist Asset Cleaning: A food factory contains complex equipment that generalist cleaners cannot service. A specialist plan must incorporate:

- High-Level Cleaning: Servicing of ceilings, high-level structures, and ventilation ductwork (AHUs) to prevent overhead contamination onto the production line.

- Confined Space Operations: Methodical cleaning of silos, vats, and tanks, requiring specialist, certified teams.

- Plant and Equipment: Deep cleaning of complex assets like conveyors, ovens, provers, and freezers.

The Precision Sector: Pharmaceuticals Cleaning Services

In the pharmaceutical sector, the focus shifts from food safety to absolute contamination control. The environment is governed by Good Manufacturing Practice (GMP), and the primary risks are particulate and microbial contamination that could compromise product integrity and patient safety.

A plan for pharmaceuticals cleaning services is one of precision, process, and validation.

Key Focus Areas for Pharmaceuticals:

- GMP Compliance: All cleaning protocols must be designed to meet or exceed the stringent requirements of GMP and support any inspections by regulatory bodies like the MHRA.

- Cleanroom and Controlled Environments: This is a highly specialised area. The plan must detail protocols for cleaning ISO 14644-classified cleanrooms, including the use of non-shedding materials, specialist filtration vacuums (HEPA), and techniques that prevent the introduction or generation of particulates.

- HVAC and Ductwork Sanitation: Air quality is paramount. A systematic plan for cleaning Air Handling Units (AHUs), ductwork, and ventilation systems is crucial to maintaining air purity and preventing the circulation of contaminants.

- High-Level Contamination Control: As in food production, overhead surfaces are a critical risk area. A methodical plan for cleaning all high-level surfaces, pipework, and structural elements prevents the settling of dust and microbes into the controlled environment below.

Beyond Food & Pharma: Hygiene for Non-Food Industries

While not always governed by the same food or drug regulations, many other cleaning solutions for a variety of industries require a specialist, process-driven approach. The common factor is a high-stakes environment where generic cleaning is insufficient.

Our work in hygiene for non-food industries demonstrates this principle of specialisation.

- Packaging Manufacturing: For producers of food-grade packaging, the hygiene standards are almost as stringent as for food itself. The plan must focus on BRCGS for Packaging standards, ensuring no contaminants (physical, chemical, or microbial) are transferred from the packaging to the food product.

- Logistics and Warehousing: Particularly for food-grade storage and distribution, a systematic hygiene plan is essential for preventing pest harborage and ensuring compliance with BRCGS for Storage and Distribution standards.

- Data Centres: In this environment, the "contaminant" is dust. A specialist plan focuses on sub-micron particulate control, using specialist equipment and anti-static methodologies to protect sensitive, high-value server equipment.

- General Manufacturing: From automotive to aerospace, a systematic plan for high-level and ventilation cleaning is essential for product quality (e.g., in paint-spraying booths) and for compliance with COSHH and other Health & Safety regulations to protect the workforce.

Why a Specialist Partner Outperforms a Generalist Provider

This brings us back to the central challenge for any Technical Manager: choosing the right partner. The difference between cleaning services for industry and specialist industry cleaning solutions lies in three key areas:

- Expertise: A generalist provider cleans. A specialist partner understands why they are cleaning. They speak the language of audits, compliance, and risk. With over 35 years of dedicated expertise in these high-stakes sectors, our core advantage is our experience.

- Reliability: Our ISO 9001, ISO 14001, and SafeContractor accreditations are not just logos. They are proof of a systematic, reliable, and safe-first approach. Our 20-year Investors in People status signifies a stable and expert workforce you can trust.

- Results: A generalist provider focuses on activity (e.g., "we cleaned for 3 hours"). A specialist partner focuses on outcomes (e.g., "the line is now allergen-free, and here is the report for your auditor").

When you engage a specialist, you are not just buying a cleaning service; you are investing in a strategic partnership that directly supports your compliance, mitigates your operational risk, and protects your brand.

Your Partner in Compliance: Building Your Bespoke Hygiene Plan

To discuss your specific operational challenges and audit requirements, contact a specialist at

Hygiene Group. A systematic partnership is the first step to verifiable hygiene excellence. Call our team directly on 0121 451 3211, email

enquiries@hygiene.co.uk, or complete our secure online form to

get a quote today.